By Andrea Casson and Riccardo Guidetti

The food system is one of the primary causes of global warming, accounting for up to 30% of greenhouse gas emissions and accounting for almost 70% of all human water consumption.

If we focus the attention on the wine supply chain, it is composed by several stages, each of which can have an impact on the level of sustainability of the finished product. These stages begin with field operations (vine planting and grape growth), continue through the winemaking process in wineries, and end with distribution, consumption, and packaging disposal scenarios.

It is clear, therefore, that with all these processes, wine farming is not immune to negative consequences on the environment. The use of fertilizers, pesticides and fuel during field activities, the transformation process and the creation of the glass bottle, which is most often not reused, can represent significant impact factors within the system.

in this context, it is becoming increasingly important to conduct assessments to determine the impact environmental of wine production and the Life Cycle Assessment (LCA) method has proven to be a valuable tool for quantifying potential impacts.

What is Life Cycle Asessment?

It is a standardized and globally recognized method through which can be quantified the potential environmental impacts of the production of a product or the provision of a Service throughout its entire life cycle.

Unfortunately, when we talk about LCA studies of the wine industry, we come across a wide range of methodological choices used which result in large degrees of unpredictability in the results and that can contribute to consolidating the perception an unreliable methodology.

Starting from these considerations, we decided to conduct a systematic review of the LCA studies related to the grape and wine production chain, providing a critical analysis of the methodological choices used and the proposed results.

Analysis showed a strong variability between studies from the design of the study through methodological choices to the way in which the results are represented and interpreted.

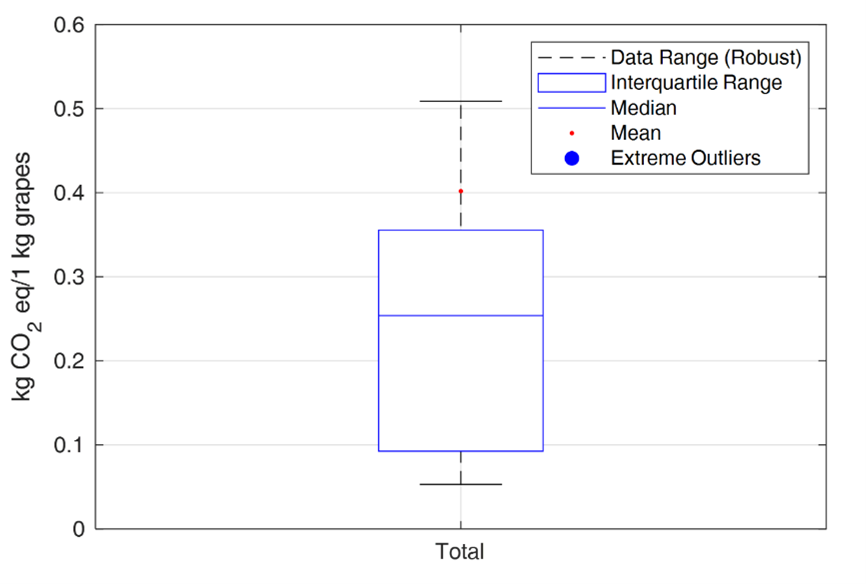

By focusing on the global warming impact category (expressed in kg CO2 eq), it was possible to classify the studies by functional unit and use the boxplot representation to quantify the variability of the results by identifying the mean, median and potential outliers.

If we focus on studies related only to field operations that report impact results per kg of harvested grape product, 40 different case studies have been identified. The analysis of the results led to the identification of a limited variability between them, not identifying outliers.

Fig. 1. Boxplot on the variability of kg CO2 eq/kg of harvested grapes

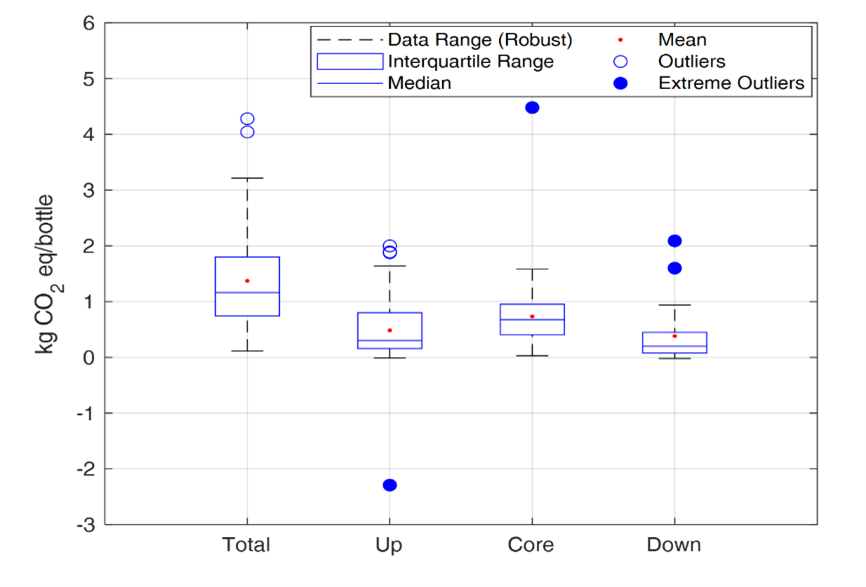

Considering instead those studies that analyze the entire production chain and consequently propose the results for 0.75 L of bottled wine, 71 case studies were selected. In Figure 2, from the field process (UP phase), the boxplot identifies an average value of 0.48 kg CO2 eq/bottle and a median value of 0.30 kg CO2 eq/bottle. Some studies have been identified as outliers, one of which refers to a negative impact value because the vineyard was assumed to be a carbon sequestration system in the design of the study. At the same time, a positive outlier derived by the high consumption of plant protection products, fertilizers and diesel during field operations.

If we analyze the vinification operations (CORE phase) these identify an average value of 0.73 kg CO2 eq/bottle and a median of 0.678 kg CO2 eq/bottle. The results showed very low variability, the winemaking and bottling phases are standardized processes that do not differ from each other. The only outlier considers in the study the aging of wine for 1 year.

The last process analyzed is the distribution and use phase (DOWN phase) where an average value of 0.38 kg CO2 eq/bottle and a median of 0.20 kg CO2 eq/bottle is identified. The outliers of this phase depend heavily on the transport systems that were considered in the study.

Fig. 2. Boxplot related to the variability of the kg CO2 eq/0.75 L of bottled wine in the total, upstream, core and downstream phase.

The variability of the result, as well as depending by nature on the different systems analyzed, was found to be strongly influenced by the differences in methodological choices, in particular we can have differences in the functional unit, the allocation procedure, the type and quality of the data, the time reference and how to estimate emissions from fertilizers and pesticides.

If the design choices of the study can vary the results, the way of representing and interpreting them is also a variability factor, for example the use of a single environmental impact indicator involves some limitations by not offering a complete picture of the analyzed scenario.

Fig. 3. Variability factors inside LCA studies

Another aspect which could be defined as the most important factor of variability is the influence of the person carrying out the LCA study. The level of knowledge and experience in performing LCA studies in the field can lead the same to make significant decisions for the expected results.

The lack of a shared and recognized methodology does not help the LCA professional to reduce the variability between studies, but contributes to increasing the variability of the result making it unreliable and not descriptive of the level of sustainability of the wine supply chain.

The creation of guideline to develop LCA analyses is fundamental in order to improve the reliability of the results. These methodological rules should be written and recognized globally so that there are real possibilities to compare very distant realities without prejudice to make the different LCA studies reliable.

Andrea Casson is a PhD student in the school of Food Systems at the University of Milano. He obtained his master degree in Food Science and technology and since the graduation he is involved in sustainability topics as LCA Expert inside the Agrifood systems. During his experience, he applied LCA at different level as sustainability evaluation of food products, processes, and systems in addition to the development of innovative methodologies to evaluate sustainability in the packaging sector including shelf-life and potential food waste or in agricultural activities to drive sustainable transition.

Riccardo Guidetti, mechanical engineer, is Full Professor in the field of biosystem engineering at the Department of Agricultural and Environmental Sciences of the University of Milan. As a research activity he has always dealt with advanced technologies for the evaluation of the quality of food products (NIR techniques, image analysis, etc.); energy analyzes and sustainable development in the food industry (Life Cycle Assessment applications); of modeling in the restaurant and wine sector. He holds courses in plant engineering for the agro-industrial and catering sectors. He is president of the Agri-food Commission and of the Machinery and Equipment Subcommittee for the agri-food sector and for Catering within the UNI framework. He is a member of the Accademia dei Georgofili and Director of the Journal of Agricultural Engineering, official organ of the Italian Association of Agricultural Engineering. He is author of more than one hundred publications.