By Carla Da Porto

About 9 million tons of grape pomace (Figure 1), the main solid by-product of wine industry consisting of skin, seeds and pulp residues, are produced in the world every year. Approximately 70% of the phenolic content of grapes is preserved in the grape pomace after the winemaking process. The recovery of the residual bioactive compounds enables to obtain high-added value biomolecules, useful in food, pharmaceutical or cosmetic industries, while simultaneously reducing the environmental impact related to its disposal.

Figure 1. Grape pomace

However, a crucial challenge in the valorization of grape pomace as an inexpensive source of polyphenols is the extraction process, which should be efficient, swift, selective, providing high solute quality and environmentally friendly.

Supercritical fluid extraction (SFE) is a green technology that enables to overcome many limitations of conventional extraction methods that are time-, energy-, and solvent-consuming procedures, raising both environmental and health & safety concerns. The most popular fluid for SFE is carbon dioxide (CO2) because of its low critical properties, low toxicity, and chemical inertness. Although CO2 is an excellent solvent for non-polar compounds, a co-solvent at low concentration can be added to modify the solvent selectivity towards polar or medium polar molecules. The SFE extracts are of superior quality compared to those obtained by conventional extraction methods. Additional SFE process advantages are low temperatures, increasing yield with lower extraction time, recyclability, (tunable) selectivity, reduced energy consumption, prevention of oxidation reactions as well as operational flexibility.

One of the most serious drawbacks reported for SFE is the initial high cost of equipment compared to those required by conventional extraction processes. However, the most common SFE applications performed on a large industrial scale such as decaffeination of tea and coffee, extraction of hop constituents and separation of lecithin from oil, demonstrate that the supercritical process can be economically viable.

Therefore, a research study was carried out on SFE of polyphenols from grape pomace, evaluating operational parameters on kinetic and modeling, in order to propose an adequate scale-up for this process and to estimate the cost of manufacturing (COM).

A SFE pilot scale equipment (Figure 2) was used to study the scale-up prediction for extraction vessels of 50, 100, 500 and 1000 liters (L) capacity.

Figure 2. SFE pilot plant at University of Udine (Italy)

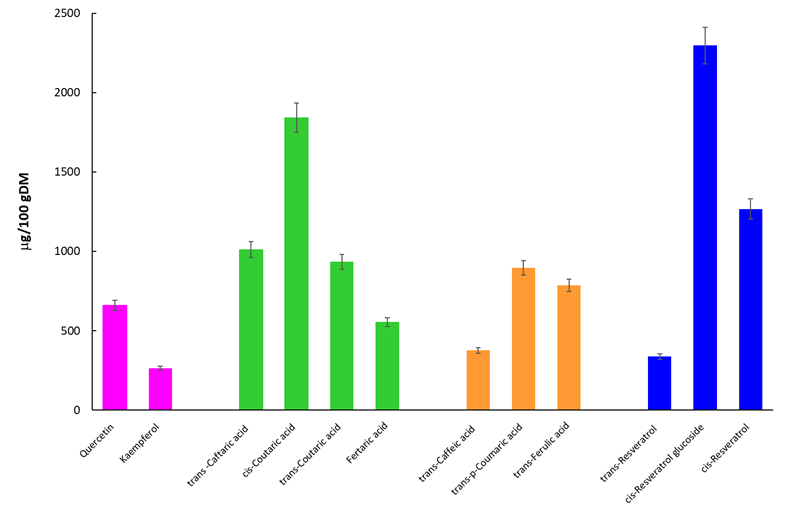

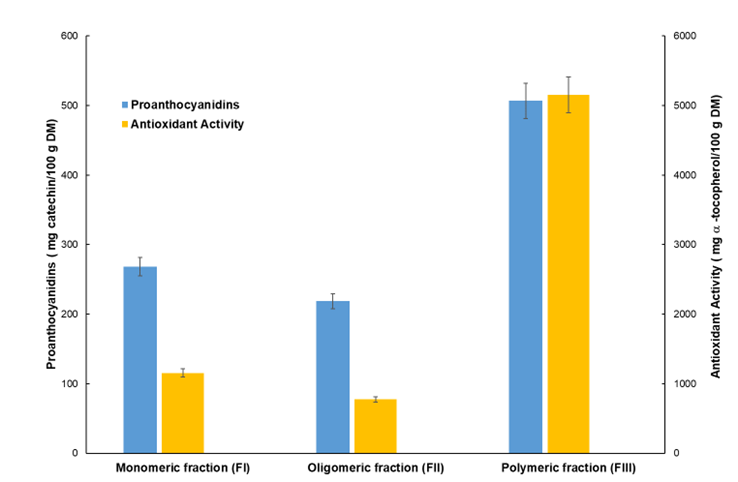

The results indicated the excellent predictive level obtained by Sovová’s model, and thus successful validation of the scale-up criteria adopted. At industrial scale, yields are close to 2.3 gGAE /100 gDM , a value obtained using the SFE pilot scale equipment. High concentrations of high-added-value phenols such as cis-resveratrol glucoside, cis-coutaric acid, trans– p-coumaric acid, quercetin (Figure 3) and proanthocyanidins (Figure 4) were found in the extract.

Figure 3. Flavonols, hydroxycinnamoyl tartaric acids, hydroxycinnamic acids and stilbenes identified and quantified in the grape pomace extract obtained at 8 MPa/ 40 °C /cosolvent 10% w/w/ 240 min.

Figure 4. Proanthocyanidins fractions and antioxidant activity of the grape pomace extract obtained at 8 MPa/ 40°C /cosolvent 10% w/w/ 240 min.

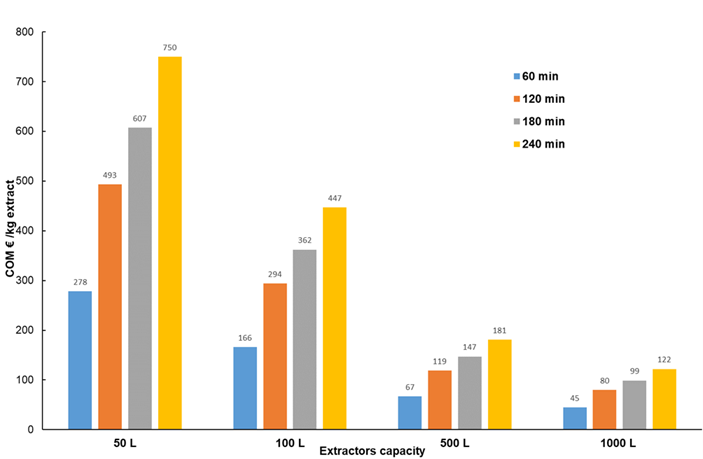

An economic evaluation of the process (Figure 5) indicated the feasibility of an industrial SFE plant with a capacity of 500 L for producing in 60 min an extract with an expected phenolics concentration of approximately 133 g GAE /kg extract at an estimated COM of 67€ /kg , better than what is currently reported in literature.

Figure 5. COM calculated for SFE units (2x 50/100/500/1000L) as a function of the extraction time.

The results obtained in this study proved that industrial-scale SFE could be developed for the separation process of polyphenols from grape pomace at a competitive cost. High quality extracts maintaining their biological activities, suitable to be used by food, cosmetic and/or pharmaceutical industries, can be produced using SFE process. SFE at industrial level could be the technological advancement required to really take off an integrated biorefinery to valorize the winery by-products so promoting a major sustainability of wine making process.

More information can be found in the original paper: https://doi.org/10.1021/acsomega.2c02631

Carla Da Porto is Associate Professor at University of Udine. She has published more than 90 papers in high and medium high IF peer-review international journals. She has participated as principal investigator or co-investigator in several national and international research projects. Her main topic of research interest is the application of ‘Green Extraction Technologies’ such as ultrasounds (UAE) and microwaves (MAE), but particularly supercritical fluid extraction (SFE), to agro-food by-products and plant species to recovery bioactive compounds of interest for food, cosmetic and pharmaceutical industry.

ORCID: https://orcid.org/0000-0002-1760-7031 , Email: carla.daporto@uniud.it