By M. Suffo , D.L. Sales , E. Cortés-Triviño , M. de la Mata , E. Jiménez

The production of agglomerated cork stoppers for the wine sector (spirits and still wines) is concentrated in several countries of Southern Europe (Spain, Portugal and Morocco), as they rely on raw material in origin to acquire the natural cork. These countries account for by 50% of the world production of cork because they host a third of the world’s oak tree surface. The Spanish cork sector produces 3 billion of stoppers annually, with 1.7 billion being used for the wine industry. The region of Andalusia (Southern Spain) is occupied by 250.000 Ha of oak tree forests and, more specifically, the province of Cádiz contains the largest Reserve of oak trees of the Iberian Peninsula (Los Alcornocales Natural Park), with about 175,000 hectares of wooded area. Half of the cork produced in Spain is extracted from this Park, with about 78,000 tons per year, an amount that is only surpassed by the neighboring country of Portugal.

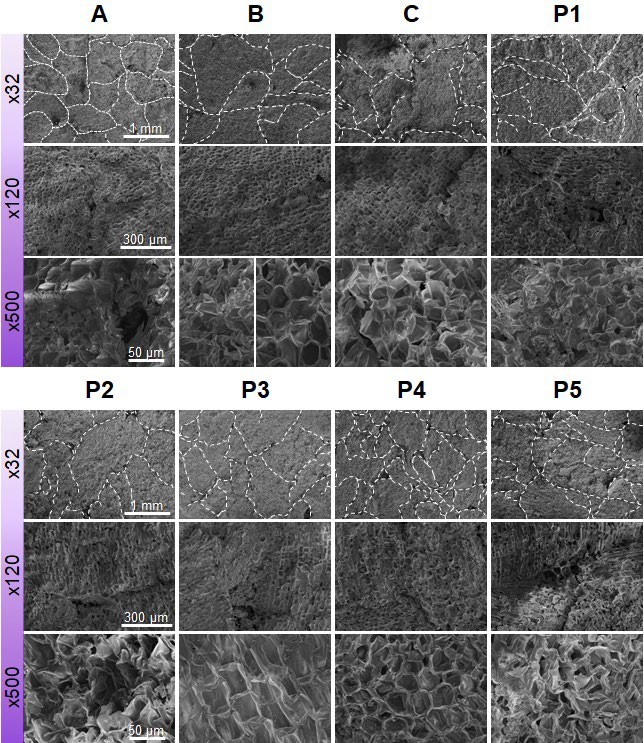

In a similar way to the epithelial tissue or the trabecular bone, one of the most outstanding properties that gives the cork its closed cell structure, is the viscoelasticity that in turn determines the resilience level. However, unlike the former that is used in tissue engineering and bone replacement, the heterogeneity of the internal structure of the agglomerated cork caused during the manufacturing process, causes a great uncertainty when its behavior is studied in relation to the orientations in which the external loads derived from normal operation are applied. Figure 1A) shows the Scanning Electron Microscope (SEM) results obtained in the different samples. The images included evidence the smoothness of sample B in contrast with the others, much rougher especially at the boundaries between neighbouring grains, usually plenty of cracks. The grain size of the cork agglomerates, as well as their distribution, can be inferred from the lower magnification images (i.e., x32), where their boundaries are highlighted by white dashed lines. The hexagonal/pentagonal prisms conforming the cork microstructure render to hexagonal/pentagonal (honeycomb-like) or rectangular (brick wall-like) patterns, when properly aligned, as shown the higher magnification images in Figure 2B). The cork cells along the axial / tangential section show rectangular cross- section, with dimensions about 20-30 µm x 40-50 µm, and 800nm thick walls approximately. Along the axial section, the cork cells show hexagonal and/or pentagonal cross-section, 20-30 μm wide, and 1 μm cell wall.

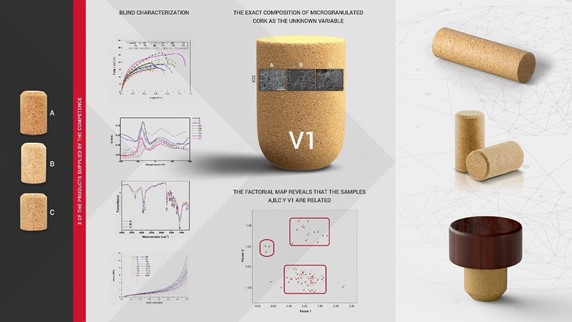

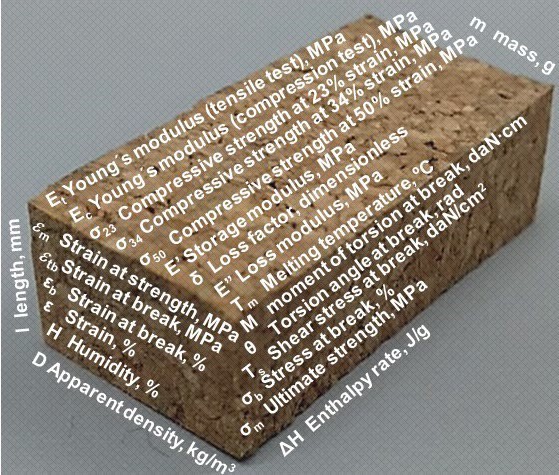

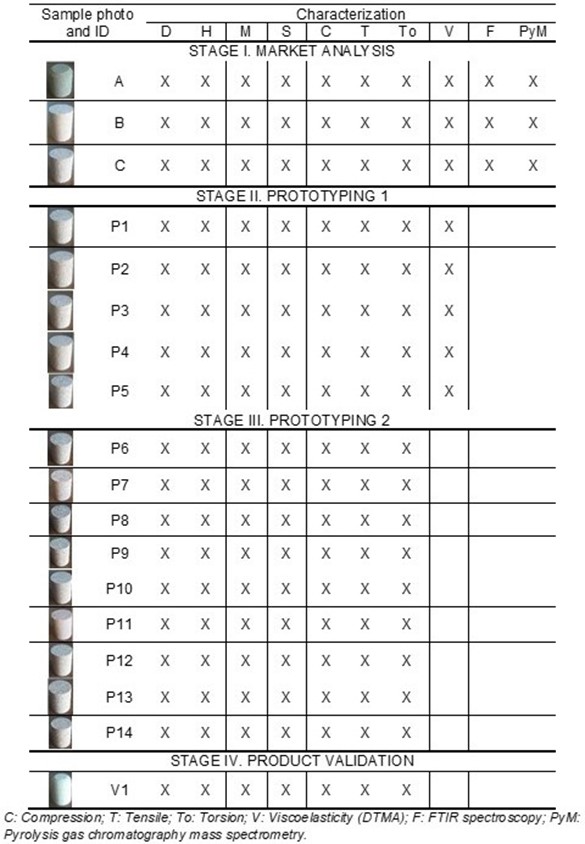

The production process of agglomerated cork stoppers for spirits and still wines involve the manufacture of an agricultural composite obtained from a natural raw material mixed with a thermoplastic system to produce a quality product that meets the standards of the wine sector packaging. To check the validity of potential products oriented for stoppers, a deep analysis of 3 international reference samples (A, B, C), with unknown compositions has been performed. Deep series of physico-chemical analyses does not reveal meaningful differences on the composition of the samples both, macro and microstructural scales, to correlate with the differentiated behavior. Complementary, mechanical tests provide a better understanding on the static and dynamic behavior of the corks in an incremental regime of temperatures. Torsion tests valuable to assess some tested variables were particularly valuable to assess some tested variables relevant despite they scarcely reported in. All this is oriented to obtain stoppers sufficiently viscoelastic to withstand the compression, traction and torsion loads associated to the processes of opening, closing and manipulation during introduction of the cork in the neck of the bottle. Although there are previous studies on AC for sparkling and still wines Spirit wines are usually consumed in a different way than the first ones, that is, they are not usually consumed at the same moment that the bottle has been opened, that is why the stopper undergoes more work cycles. Currently, high uncertainty is still present during the decision-making process to define the parameters that better characterize the material as too many variables must be used to standardize a universal characterization method. Through a blind characterization where the “composition” is an unknown variable. We start the study with three samples (A, B, C) picked from commercial “premium” brands. To analysis 23 different variables (figure 2), a series of chemical-physical-mechanical tests are applied both, at micro- and macro-structural levels, to a set of 18 sample batches of AC (Table 1).

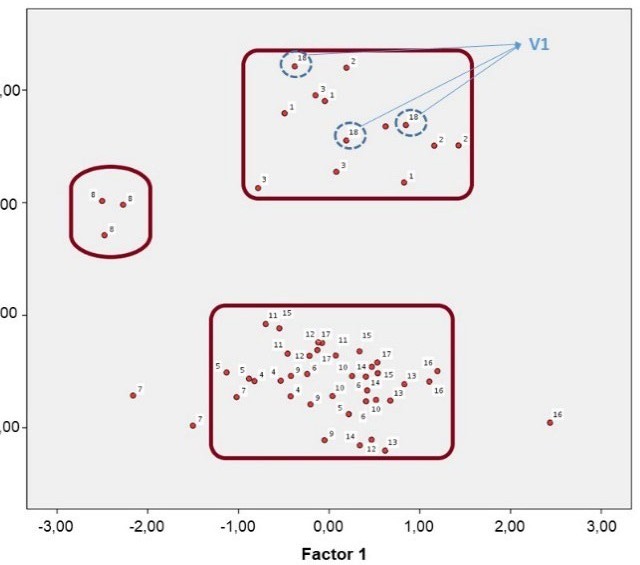

The factorial analysis (FA) method allows to group all the variables measured into 3 sets delimited by factors 1 and 2, with an explanatory level of 50%,approximately. These groups of variables are categorized according to their level of explanatory importance as follows:

- σ23, σ34, σ50, M, Ts; (first-order variables that mainly contribute to explain the results of the tests carried out with the cork batches and aimed at assessing their differential behavior).

- σm , εm, εtb , D; (secondary variables that explain 65 % of the multivariate behavior of cork).

The factorial scores of the experimental measurements and their group behavior, labeled according to the explored variable “composition” reveal the homogeneity between the variables in all the experiments except AC samples with composition 7, 8 and 16 (figure 3). In the case of samples 1 (A), 2 (B), 3(C) and 18 (V1), it is especially relevant the correlation found between the 3 comertial batches (Stage I) and the last prototype that has currently become the first commercial product in the market. This confirms the validity of both the test method and the statistical analysis, while points out the expected performance of the new product in the market, evolving according to the law of supply and demand.

The statistical exploration methodology based on unsupervised factor analysis technique will influence decision-making when selecting the prototype of AC stoppers for spirits and still wines that leads to the successful placing on the market by “Herederos de Torrent Miranda”, a local manufacturer whose brand of capsules and closures has been known for more than 100 years.

Miguel Suffo, Engineer, MSE in Information Technology in Manufacturing (TIF) from the Polytechnic University of Madrid (1995) and Ph. D. from the University of Cádiz (UCA, 2013). He is a lecturer at the Department of Mechanical Engineering and Industrial Design of the Higher School of Engineering (UCA) since 1996, being Associate Professor since 2005. He has been also awarded with the Cepsa-UCA Chair (Energy and Environment) in 2005 and with the Verinsur-UCA Chair (Recovery of waste) in 2018. Between 2001 and 2011, he was a member of the Materials Technology Research Group (TEP-136) to join subsequently the Environmental Technology Research Group (TEP-181) where he develops his research activities at the moment. He owns 4 international patents currently under exploitation and has published 20 publications in journals indexed in the Science Citation Index. He has participated in more than 40 reserach transfer grants with private companies and in 4 competitive research and development projects, acting in one of them as a principal investigator (PI). His current line of research focuses on the recovery of strategic waste following the principles of the Circular Economy and in the reduction of the carbon footprint. Furthermore, he also works on the design and additive manufacturing of non-metallic biomechanical prostheses for application in traumatology and scaffolds for tissue engineering and bone regeneration.