The winemaking activity involves processing grapes to produce wines and juices, leading to a significant amount of waste, with skins, stems, and seeds accounting for approximately 30% of the grape’s weight [6]. In 2020, the country produced slightly over 1.5 million tons of grapes, with 70% of that amount being used for making wines and juices, resulting in substantial waste volumes. While these waste materials have potential applications in the food, pharmaceutical, and cosmetic industries, their demand is currently not very significant, raising concerns about proper environmentally-friendly disposal [2,7].

The improper disposal of this waste poses an environmental liability for companies. As a result, it becomes crucial to devise strategies for its environmentally responsible management, with a focus on its (re)utilization. On a global scale, a World Bank report [8] highlights that roughly 2.01 billion tons of waste are generated annually, and this figure is projected to rise to 3.40 billion tons by 2050, representing an increase of nearly 70%. To mitigate this impact, numerous countries must heavily invest in technology, innovation, and sustainability [7,9].

The red ceramic industry has emerged as a viable solution for managing organic waste by incorporating it into the ceramic mass or utilizing it as a source of thermal energy in ceramic furnaces. These waste materials, referred to as fuel waste [10,11], offer a high calorific value due to their substantial carbon content, resulting in reduced energy consumption during the firing process.

Several published studies [[12], [13], [14], [15]] have highlighted the potential of adding fuel waste from various industrial activities, such as rice husks, coconut fiber, effluent treatment plant waste, and sugarcane bagasse, in masses for ceramic product formulations. This not only helps in reducing environmental impacts but also leads to improved technological properties of ceramics and enhances the firing stage.

While incorporating waste into the ceramic mass for red ceramics is feasible and beneficial, it demands caution due to potential adverse effects, such as increased water absorption and decreased mechanical strength. Consequently, determining an acceptable percentage of incorporation becomes crucial. This study focuses on assessing the feasibility of incorporating waste from the wine industry, specifically the skin of the Isabel grape (Vitis labrusca), into the red ceramic mass. The primary objective is to evaluate the technical aspects, particularly the physical and mechanical properties. Additionally, this research aims to contribute not only to reducing energy consumption during the firing stage but also to promoting environmentally friendly waste disposal.

Regarding the incorporation of waste from wine processing, there have been only a few published studies exploring this type of biomass [[16], [17], [18]]. However, these studies differ from the current work in terms of the specific residues used, processing conditions, granulometry, specimen conformation, formulations, and firing temperatures. Therefore, the lack of research on incorporating Isabel grape skin into the ceramic mass and studying its physical and mechanical properties, coupled with the importance of utilizing these residues and avoiding improper disposal, served as the primary motivation for undertaking this study.

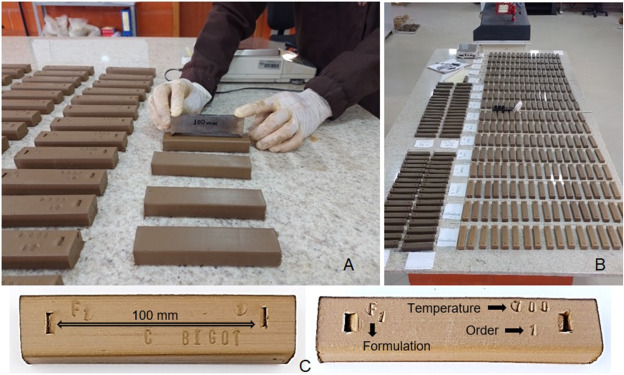

This study examines the potential of adding grape skins to red ceramics to evaluate its effect on the physical and mechanical properties of the clayey body. Five compositions were prepared with different percentages of biomass incorporation: 0%, 2.5%, 5%, 7.5%, and 10%. The specimens were conformed using vacuum extrusion in a laboratory extruder, with dimensions of 120 mm in length and a straight section of 30 × 15 mm. After drying, the pieces were sintered in a laboratory muffle furnace at 700 °C, 800 °C, 900 °C and 1000 °C. Chemical, mineralogical, thermal, physical, morphological, and microscopy tests were conducted on the clayey raw materials.

Fig. 1. (A) fresh grapes; (B) – Waste collection after processing.

Table 1 presents the key constituents of the biomass, which generally contains a high concentration of carbon (42.10%) and oxygen (37.86%). This composition is attributed to the presence of lignin (28.91%), a phenolic macromolecule abundant in carbon, contributing to increased calorific power during burning. Additionally, the biomass contains polysaccharides linked to holocellulose (32.82%), compounds found in wood that leave a substantial carbon footprint.

The study’s results revealed that the optimal formulation for the clayey body was achieved by incorporating up to 5% of Isabel grape skin biomass (Vitis labrusca) and sintering at 900 °C. For water absorption, incorporating up to 5% of biomass and firing at 700 °C meets the normative limits for the production of structural blocks and sealing blocks. However, firing at 900 °C meets the most restrictive parameter intended for making roof tiles due to greater material densification, resulting in decreased water absorption.

The linear shrinkage of the pieces when fired up to 900 °C is minimally affected by the incorporation of up to 5% biomass. At temperatures from 700 to 800 °C, the shrinkage remains below 2%, meeting the maximum linear shrinkage value for tiles.

Fig. 2. Clayey body the extruded and their nomenclatures.

Concerning the bending strength parameter, at 700 °C firing, there was a proportional increase in strength with higher biomass incorporation. This improvement is believed to be associated with the presence of complex and thermally more stable structures in the biomass. At 800 and 900 °C firing, there was a gradual decrease in bending strength, attributed to the incorporation of biomass. At 1000 °C, there was a sudden reduction in bending strength values for all formulations with biomass incorporation, likely due to the concentration of stresses in the microstructural “defects” promoted by the addition of biomass, while the reference mass showed an increase in strength.

Hence, utilizing waste from wine production in the ceramic industry presents a remarkable opportunity for proper waste management within the circular economy framework. This approach not only contributes as a strategic solution to add value to the waste but also aids in environmental conservation, mitigating the challenges posed by waste disposal significant and escalating concern worldwide.

Read all at: https://doi.org/10.1016/j.jmrt.2023.08.224

Elvis Pantaleão Ferreira, Geovana Carla Girondi Delaqua, Gabriela Nunes Sales Barreto, Sérgio Neves Monteiro, Ednaldo Miranda de Oliveira, Carlos Maurício Fontes Vieira,

Incorporation of wine industry waste into red ceramic: study of physical and mechanical properties, Journal of Materials Research and Technology, Volume 26, 2023, Pages 5748-5761,