By Karine Inês Bolson Moro

Grape pomace is the main solid residue in the wine chain, representing 20% to 30% of the total volume of vinified grapes, consisting mainly of skin, seeds and pulp residues. The treatment and disposal of the by-product represent an economic and environmental challenge, since only 3% of this waste is recovered or reused (Garrido et al., 2019). Studies have shown the potential for using wine residue in human food, due to the high content of dietary fiber and phenolic compounds, which remain in the grape pomace after its extraction and transfer to wine (Bender et al., 2020). In recent years, cleaner and more environmentally friendly extraction methods have been developed and improved for the extraction of phenolic compounds (Moro et al., 2021), with the purpose of including safe and quality products in food products.

Due to high levels of fibers and phenolic compounds (anthocyanins, flavonols, flavanols, resveratrol and phenolic acids), coming from secondary plant metabolites, and which have antioxidant and radical scavenging properties, with potential health benefits (Caldas et al., 2018; Garrido et al., 2019). Therefore, the reuse of this by-product has great potential but it is still little reused at the industrial level due to the lack of optimization of fast and efficient techniques for extracting these compounds. The green extraction is based on the design of processes that reduce energy consumption and allow the use of alternative, renewable solvents that ensure safety and quality products (Moro et al., 2021). Extraction is the most important step in the recovery, isolation, and identification of compounds present in extracts, and the choice of solvent is crucial in green extraction processes. These should be 100% natural, nontoxic, biodegradable, suitable for installations, with low emissions of volatile organic compounds and that at the end of the process, allow their recovery (Chemat et al., 2019).

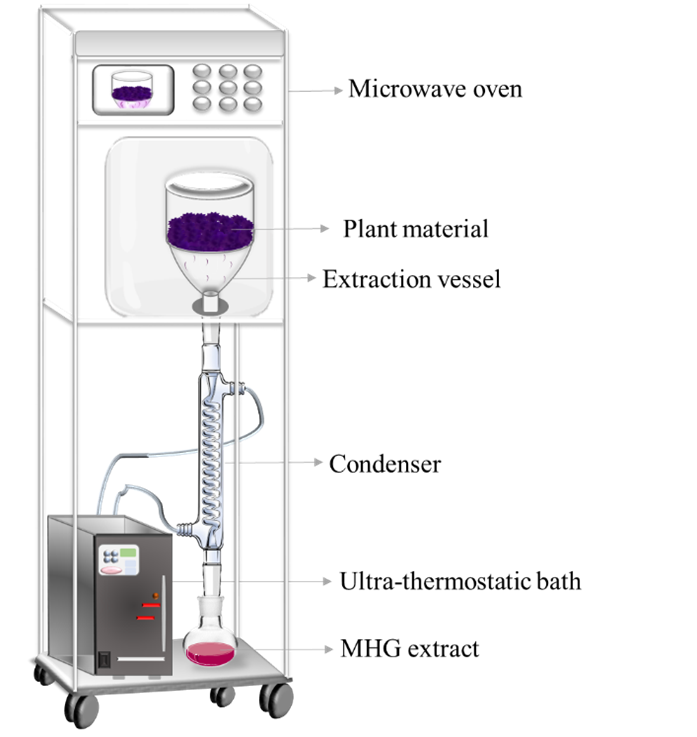

The microwave hydrodiffusion and gravity (MHG) technique was developed by Chemat et al. (2008), and it is a solvent-free extraction method that combines microwave heating with earth gravity at atmospheric pressure (Moro et al., 2021). The technique exploits the dielectric heating of water and “in situ” molecules present in cells, heating plant material immediately. The increase in temperature and pressure inside cells promotes the elongation of the structure leading to physical rupture of the membrane and cell wall. This physical phenomenon, known as hydrodiffusion, allows the extract loaded with photochemical compounds and cell water to diffuse from the plant material and carried by gravity, and then the extract enters the cooling system outside the microwave through a perforated disc of Pyrex material , where it is collected in a specific balloon (Moro et al., 2021). The MHG system was designed for industrial and laboratory-scale applications in the extraction of pigments, aromatic components, and antioxidants from plant materials with a minimum of 60% of initial moisture. MHG produces microwaves with precise temperature control, avoiding gradients and thermal degradation of the compounds of interest. In addition, the concept of bio-refinery can be applied, offering operational advantages derived from the reduction of solvents, energy, waste and time (Boukroufa et al., 2015; López-Hortas et al., 2016).

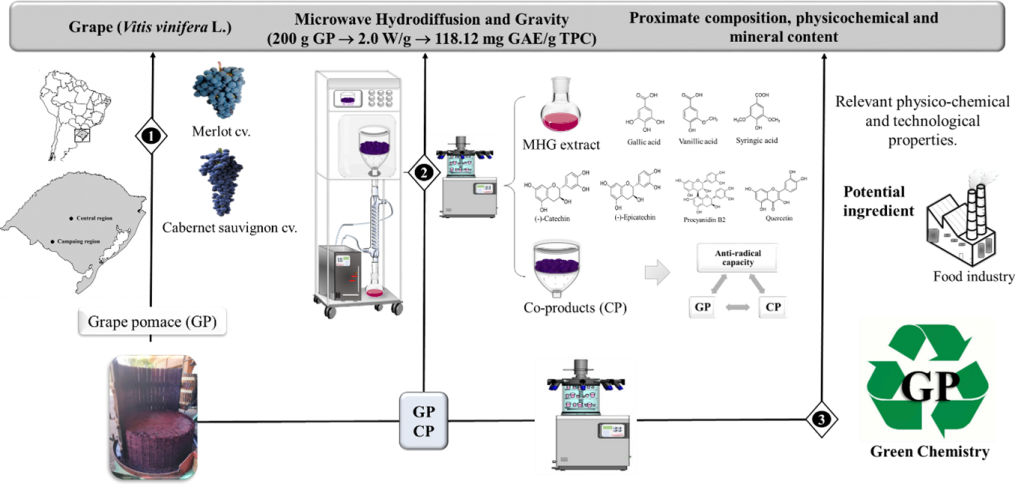

Therefore, the aim of the study was to use the MHG technique to extract polyphenolic compounds from grape pomace. The grape pomace of the red Merlot and Cabernet Sauvignon cultivars were obtained after the fermentation stage and submitted to the extraction process by MHG. The extracts obtained were evaluated for phenolic identification and antioxidant activity and the remaining residue from the extraction process, co-product (CP), was evaluated for its proximate, physicochemical, mineral and antioxidant composition.

The MHG extraction method proved to be efficient to recover polyphenolic compounds from grape pomace. The results demonstrate that in less than 10 minutes of irradiation it is possible to obtain satisfactory extraction results. We found that the power of 2 W/g for 200 g of plant material allows extracting the entire colored fraction of the grape pomace. Polyphenols of four distinct classes were identified in the present study: gallic, syringic and vanillic acids (hydroxybenzoic acids), procyanidin B2 (proanthocyanidin), catechin and epicatechin (flavan-3-ols), and quercetin (flavonol) The polyphenolic extracts obtained present considerable amounts of polyphenols, as well as expressive antioxidant activity. The results demonstrate that, in the condition of optimized extraction, it is possible to obtain from the grape pomace sustainable, fast and safe production of polyphenolic compounds.

In addition, we identified that the residue remaining from the process, a co-product, has relevant physicochemical and technological properties, being a potential ingredient in the food industry. The co-product can be incorporated individually or together with the extract, in food products such as breads, cakes, cookies, snacks, cereal bars, etc. Therefore, enabling a complete recovery of the grape pomace and allowing the development of natural and healthy products.

The treatment and destination of grape pomace represents an economic and environmental challenge for the wine industry, however, it can become a nutritional and economic source. The MHG extraction method applied to grape pomace is clearly advantageous and our study demonstrates that it is possible to obtain satisfactory extraction results. We expect that in the future, the amount of composted grape pomace may be reduced as the more profitable use of bioactive grape pomace compounds is utilized. The method used here is a clean method and fits the principles of green chemistry, as it does not require the use of organic solvents and meets consumer demand for healthier food products with a natural character.

Read more at: https://doi.org/10.1016/j.lwt.2021.112066

Karine Inês Bolson Moro – Ph.D. student, Food Science and Technology. Undergaduate in Food Technology (2014). Special Graduate Program for Teacher Training for Professional Education at the Federal University of Santa Maria (2015). Master in Food Science and Technology from the Federal University of Santa Maria (2016). Specialist in Food Science – Fruit and Vegetable Technology at the Federal University of Pelotas (2017). Technician in Work Safety by the Industrial Technical College of Santa Maria (2019). She is currently a Ph.D. student at the Graduate Program in Food Science and Technology at the Federal University of Santa Maria. Currently, she works in the areas of Food Science and Technology, mainly on the following topics: reuse of agro-industrial residues, bioactive compounds, green technologies, microencapsulation and development of new products.

- Silva, L. P., & Penna, N. G. (2020). Effects of micronization on dietary fiber composition, physicochemical properties, phenolic compounds, and antioxidant capacity of grape pomace and its dietary fiber concentrate. LWT, 117, 108652. https://doi.org/10.1016/j.lwt.2019.108652

- Boukroufa, M., Boutekedjiret, C., Petigny, L., Rakotomanomana, N., & Chemat, F. (2015). Bio-refinery of orange peels waste: A new concept based on integrated green and solvent free extraction processes using ultrasound and microwave techniques to obtain essential oil, polyphenols and pectin. Ultrasonics Sonochemistry, 24, 72–79. https://doi.org/10.1016/j.ultsonch.2014.11.015

- Caldas, T. W., Mazza, K. E. L., Teles, A. S. C., Mattos, G. N., Brígida, A. I. S., Conte-Junior, C. A., Borguini, R. G., Godoy, R. L. O., Cabral, L. M. C., & Tonon, R. V. (2018). Phenolic compounds recovery from grape skin using conventional and non-conventional extraction methods. Industrial Crops and Products, 111, 86–91. https://doi.org/10.1016/j.indcrop.2017.10.012

- Chemat, F., Abert-Vian, M., Fabiano-Tixier, A. S., Strube, J., Uhlenbrock, L., Gunjevic, V., & Cravotto, G. (2019). Green extraction of natural products. Origins, current status, and future challenges. TrAC – Trends in Analytical Chemistry, 118, 248–263. https://doi.org/10.1016/j.trac.2019.05.037

- Chemat, F., Vian, M. A., & Visinoni, F. (2008). Microwave hidrodiffusion for isolation of natural products.

- Garrido, T., Gizdavic-Nikolaidis, M., Leceta, I., Urdanpilleta, M., Guerrero, P., de la Caba, K., & Kilmartin, P. A. (2019). Optimizing the extraction process of natural antioxidants from chardonnay grape marc using microwave-assisted extraction. Waste Management, 88, 110–117. https://doi.org/10.1016/j.wasman.2019.03.031

- López-Hortas, L., Conde, E., Falqué, E., & Domínguez, H. (2016). Flowers of Ulex europaeus L. – Comparing two extraction techniques (MHG and distillation). Comptes Rendus Chimie, 19(6), 718–725. https://doi.org/10.1016/j.crci.2015.11.027

- Moro, K. I. B., Bender, A. B. B., da Silva, L. P., & Penna, N. G. (2021). Green Extraction Methods and Microencapsulation Technologies of Phenolic Compounds From Grape Pomace: A Review. Food and Bioprocess Technology. https://doi.org/10.1007/s11947-021-02665-4

- Singla, M., & Sit, N. (2021). Application of ultrasound in combination with other technologies in food processing: A review. Ultrasonics Sonochemistry, 73, 105506. https://doi.org/10.1016/j.ultsonch.2021.105506