By George-John E. Nychas

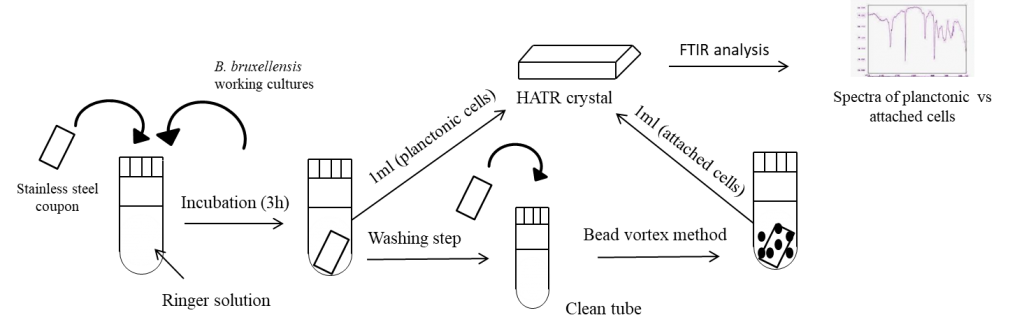

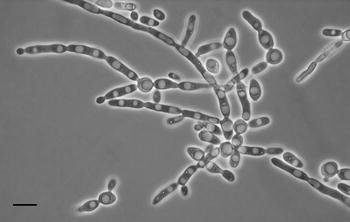

The involvement of microorganisms in winemaking process has been a subject of interest for years due to their both beneficial and spoilage action. Brettanomyces bruxellensis is a wine spoilage yeast species characterized by a high level of persistence in winery environments due to its biofilm formation capacity on both biotic and abiotic surfaces. The characteristic of this species to contaminate wine cellars and at the same time displaying high resistance to cleaning antimicrobial agents, is a cause of concern for the wine industry. However, the knowledge on the biofilm formation capacity of B. bruxellensis remains limited. In the present study investigated the biofilm formation of 11 B. bruxellensis strains to stainless steel coupons, after 3 hours of incubation in aqueous solution. The process is illustrated in Figure 1.

It was revealed that B. bruxellensis strains were able to develop biofilms although their capacity to form biofilms on stainless steel surfaces, differed significantly, as has already been observed for other phenotypic traits with oenological interest. This was also the case with the lactic acid bacteria of wine, especially the Oenococus oeni species, have also the ability to form biofilms on stainless steel surfaces, while the attached cells contribute to the aromatic profile of the wine .

The potential of using non-destructive methods (e.g. FTIR or Multi Spectral Imaging ) to (i) overcome the limitations of conventional food microbiology and (ii) automatic monitoring of food processes in all stages of the food chain has been extensively used to either to assess food quality or to evaluate microbial loads on foods. Limited studies have been considered to use this approach in biofilms.

Thus in this study FTIR analysis was performed for both planktonic and attached cells while the comparison of the obtained spectra revealed the chemical groups implicated in biofilm formation process. The greater region of polysaccharides and lipids clearly discriminated the obtained spectra while the absorption peaks at the specific wavenumbers possibly revealed the presence of β-glucans, mannas and ergosterol.

The main restriction of the above-mentioned approaches i.e. using FTIR, is related to (big) data derived from these analytical spectra and expression profiles that can be considered as unique fingerprints. So far, the combination of data mining and data analysis of the measurements acquired from sensors have been applied in various biological systems but their application is limited if any in food microbiology and even more to study of biofilms.

In this study unsupervised clustering and supervised classification were employed to identify the important wavenumbers of the whole spectra. The fact that all the metabolic fingerprints of the attached versus the planktonic cells are similar within the same cell phenotype class and different between the two phenotypes implies a clear separation of the cells’ phenotype; supported results of the developed classification model.

This study succeeded for the first time to apply a non-invasive technique to reveal the metabolic fingerprint implicated in biofilm formation capacity of B. bruxellensis, underlying the homogenous mechanism within the yeast species.

The results obtained from the present study reveal that the biochemical changes occurring during biofilm formation seem to be homogenous for B. bruxellensis suggesting a common adaptation strategy within the species. Exploiting this outcome, we are able to develop a prediction model for efficient and reliable for phenotype assessment, planktonic vs. attached cells, for the specific strain and culture. It would be interesting in the future to prove that the developed prediction model has no limitation regarding the used strain or culture.

Read all at: https://doi.org/10.3390/microorganisms9030587

George- John Nychas is Professor in Food Microbiology in the Dept of Food Science & Human Nutrition of Agricultural University of Athens (Greece). The last 28 years coordinated 6 European Projects and participated in more than 35 EU projects (budget >12 M €). Through these projects, the team of Prof. G-J., Nychas has acquired extensive experience on; (a) on food safety – risk analysis (b) implementation of Process Analytical Technology (PAT) and Internet of Things (foods) in the food industry via the introduction and utilization of sensors (nondestructive non- invasive) and Data Science. So far (June 2021), he has published 292 papers with ca. 15300 citations and h=72 [Scopus].

Currently, he is (i) Chairman of food safety group of European Technological platform food for life (ii) member of the pool of scientific advisors on risk assessment for DG SANCO, (iii) member of the Higher Education while he served as (a) co-chair (2008-2010) in the Professional Development Group of “Microbial Modeling and Risk Analysis” of International Association for Food Protection (IAFP), (b) member of the Biohazard panel of EFSA (c) the Advisory Forum of EFSA (d) external expertise to the European Parliament and (e) President of the Greek Food Authority.

Recently (Nov 2018) he was listed among the top 0.1% of highly cited researhers in the field of Agriculture Science (Web of Knowledge – Clarivate), while he was awarded the Degree of Doctor of Science (DSc, University of Bath, UK) and the International Leadership Award from the IAFP (USA). Finally, more than fifteen (15) of his Ph.D. students have been employed as professors (5) and senior researchers in national and international universities and research institutes.