By Alberto De Iseppi, Giovanna Lomolino, Matteo Marangon, Andrea Curioni

Food and wine production processes have a relevant environmental impact due to both the inputs (e.g. energy, raw materials) and the outputs produced, with the latter mainly represented by greenhouse gasses and wastes which generally require to be disposed of. The main by-products of wine production are wastewaters, grape pomace, grape stalks and wine lees. The growing attention to circular economy approaches represents an opportunity for the wine industry to both reduce the disposal costs and to improve the environmental and economical sustainability of the wine supply chain. In this scenario, the exploitation of grape pomace (containing both skins and seeds) to obtain products as spirits, grape seed oil, and for extracting additives like polyphenols is already well established (Bordiga, 2015), while wine lees, the second largest by-product of winemaking, so far have received only a modest attention regarding their possible valorisation.

Wine lees are a sludge material made of yeast cells and other insoluble particles that accumulates at the bottom of wine tanks after the alcoholic fermentation. Wine lees are rich in organic compounds, and therefore have an high biological and chemical oxygen demand that make them environmental pollutants.

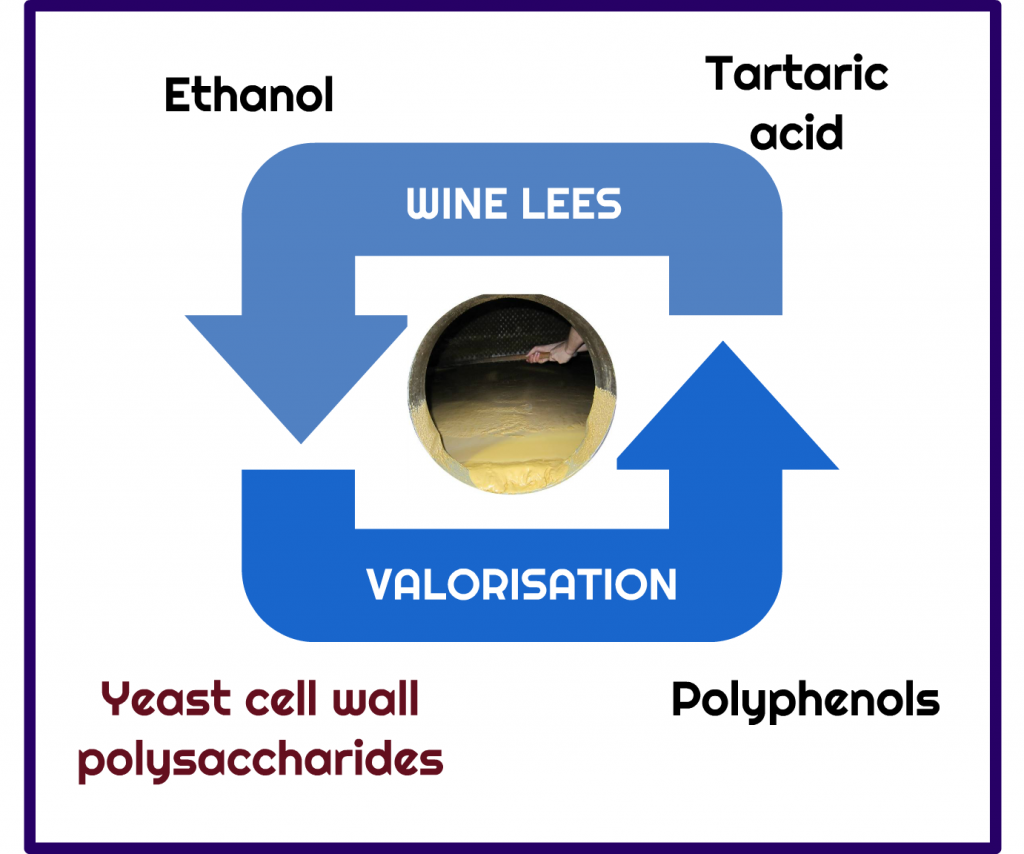

Currently, residual ethanol is regularly recovered from wine lees to comply with the European Regulation No 479/2008. Additionally, methods for tartaric acid extraction are occasionally applied on large scale. However, these recovery strategies do not fully valorise this by-product. For instance, wine polyphenols could also be extracted from red wine lees by using various food-grade organic solvents (i.e. ethanol).

To date, the most comprehensive approach to accomplish a complete exploitation of both the liquid and solid fractions of wine lees includes the extraction of ethanol, tartaric acid and polyphenols from the liquid part, and the use of the solid residue (yeast biomass) as a substrate for microbial growth (Kopsahelis et al., 2018). However, one relevant obstacle for the industrial uptake of this approach is represented by the high variability of wine lees’ composition which may be a problem for the production of standardized fermentation media. Therefore, other strategies should be investigated for the valorisation of the yeast biomass in wine lees, and the recovery of yeast cell wall’s mannoproteins and β-glucans could represent a viable option, as already established for the yeast biomass deriving from brewing.

β-glucans, the primary constituent of the yeast cell wall (35 – 55%), have been studied as functional ingredients since the 1940s (Liu, Wang, Cui, & Liu, 2008) thanks to their proven immunostimulatory, antioxidant and cholesterol-reducing properties that allowed them to be included in the “list of novel food components” (Regulation (EC) No 258/97). Furthermore, β-glucans can affect the physicochemical and rheological properties of foods by acting as thickeners. Indeed, thanks to these properties, they have been applied as fat-replacers for the preparation of low-fat mayonnaise. β-glucans extracted from brown algae (Laminarin) have been used as plant elicitors as, when sprayed, they promote the plant’s natural response against pathogens as Plasmopara viticola and Botrytis cinerea. Nevertheless, also yeast β-glucans are, in some cases, included in commercial formulations for downy mildew (Plasmopara viticola) control in viticulture.

The second major component of the yeast cell wall are mannoproteins, complex polysaccharides located in the cell wall’s external layer constituted of mannose chains attached to a protein backbone (Cameron, Cooper, & Neufeld, 1988). Yeasts naturally release mannoproteins in wine during fermentation and aging thus contributing to enhance wine foamability, protein and tartrate stability, as well as mouthfeel. These characteristics led to the commercialization of mannoprotein-based preparations as wine additives. However, these compounds are generally extracted from yeast grown in biotechnological reactors rather than from winemaking by-products as wine lees. A particularly appealing characteristics of mannoproteins is that, thanks to their amphipathic nature, they can efficiently act as emulsifiers in food preparations as demonstrated by studies with mannoproteins from beer lees.

Therefore, considering the various applications that yeast extracts have been demonstrated to have in food and wine, we propose to extract both mannoproteins and β-glucans from wine lees in order to fully exploit this by-product. Indeed, a hypothetic valorisation strategy of wine lees could include the recovery of the cell wall polysaccharides after ethanol, tartaric acid and polyphenols extractions. In particular, following the integrated protocol purposed by Silva Araújo et al.(2014), the yeast biomass recovered from the brewing process could initially undergo an autoclave treatment to destabilize the yeast cell walls so to release the mannoprotein fraction into the liquid phase. In this manner, these compounds can be separated, and the remaining insoluble β-glucan-rich fraction can be processed through some purification steps including a lipid extraction and an enzymatic hydrolysis of the protein residues that will finally yield yeast β-glucans suitable for applications in food and other preparations.

According to the literature, some of the limitations in moving this approach from beer to wine lees could be the presence of polyphenols which could interact with the mannoproteins thus limiting their purity in the extract. Additionally, the possible significant inclusion of pesticides deriving from vineyard treatments must be studied. However, although these issues need to be fully investigated, a simple solution to avoid these potential problems should be to use lees derived from white winemaking and organically grown grapes.

In summary, future by-product valorisation strategies of wine lees will need to adopt an integrated approach tailored to extract the highest number and amount of compounds with potential applications in different sectors, thus improving also the environmental and economic sustainability of the whole wine supply chain.

See more about this in: https://www.sciencedirect.com/science/article/abs/pii/S096399692030377X

Alberto De Iseppi

Matteo Marangon

Andrea Curioni

Alberto De Iseppi is a Ph.D. Student at the Land Environment Resources and Health (LERH) PhD Program of the University of Padua. In the same University, he earned his BSc and MSc in Food Science and Technology. His research project is focused on the extraction of yeast polysaccharides from wine lees for food and oenological applications. In 2019, he spent 6 months at Stellenbosch University as a visiting Ph.D. student. His research outcomes have already been the subject of scientific papers and conference contributions.

After obtaining her PhD in Applied biocatalysts and industrial fermentation, Giovanna Lomolino spent 10 months in the University of Georgia (USA) investigating genes involved in the yeast cell cycle. In 2000 Giovanna returned to Padova to work as Post-Doc, and in 2006 became Researcher. Since 2018 Giovanna is an Associate Professor in Food Science and Technology at Department of Agronomy, Food, Natural resources, Animals and Environment (DAFNAE) of the University of Padova, and her research is focussed on sensory analysis of traditional and innovative foods, study of the physical and rheological characteristics of foams, emulsions and fluids (e.g. wines), and on the study of enzymes of food technological interest.

After obtaining a PhD in Oenology from the University of Padua (Italy) Matteo Marangon joined the Australian Wine Research Institute to work as a Researcher. In 2014 Matteo joined Plumpton College (UK) to lead a Master of Science in Viticulture & Oenology, before returning to the University of Padova in 2016. Matteo is currently an Associate Professor, and his research is focussed on the study of wine instabilities and wine colloids. Matteo has authored over 80 publications, including 29 indexed in Scopus.

Andrea Curioni is full professor of Food Science and Technology at Department of Agronomy, Food, Natural resources, Animals and Environment (DAFNAE) of the University of Padova, and member of the Interdepartmental Center for the Research in Viticulture and Enology (CIRVE). In addition to the teaching activity in the fields of enology and food chemistry, his research focuses mainly on several aspects of food biochemistry and in particular on the study of macromolecules involved in food and wine quality.

References

- Bordiga, M. (2015). Valorization of Wine Making By-Products. https://doi.org/10.1201/b19423

- Cameron, D. R., Cooper, D. G., & Neufeld, R. J. (1988). The mannoprotein of Saccharomyces cerevisiae is an effective bioemulsifier. Applied and Environmental Microbiology, 54(6), 1420–1425. https://doi.org/0099-2240/88/061420

- Kopsahelis, N., Dimou, C., Papadaki, A., Xenopoulos, E., Kyraleou, M., Kallithraka, S., … Koutinas, A. A. (2018). Refining of wine lees and cheese whey for the production of microbial oil, polyphenol-rich extracts and value-added co-products. Journal of Chemical Technology and Biotechnology, 93(1), 257–268. https://doi.org/10.1002/jctb.5348

- Liu, X. Y., Wang, Q., Cui, S. W., & Liu, H. Z. (2008). A new isolation method of β-d-glucans from spent yeast Saccharomyces cerevisiae. Food Hydrocolloids, 22(2), 239–247. https://doi.org/10.1016/j.foodhyd.2006.11.008

- Regulation (EC) No 258/97 of the European Parliament and of the Council of 27 January 1997 concerning novel foods and novel food ingredients. (1997). Retrieved from https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:01997R0258-20090807&from=EN

- Silva Araújo, V. B. Da, Melo, A. N. F. De, Costa, A. G., Castro-Gomez, R. H., Madruga, M. S., Souza, E. L. De, & Magnani, M. (2014). Followed extraction of β-glucan and mannoprotein from spent brewer’s yeast (Saccharomyces uvarum) and application of the obtained mannoprotein as a stabilizer in mayonnaise. Innovative Food Science and Emerging Technologies, 23, 164–170. https://doi.org/10.1016/j.ifset.2013.12.013