by Anastasios Nikolaou

Nowadays, the multiple technological advantages offered by immobilized cells in fermentations like improved fermentation productivity, cell control and cell stability, application of continuous system configurations, enhancement of cell viability and ability for cell recycling, and improved final product quality have been well documented (Kourkoutas et al., 2004) and the positive effects of immobilization technology in winemaking have been well established. Multiple immobilization supports have been proposed over the past years for use in winemaking. However, the high pressure created on high-capacity bioreactors usually results in destruction of most organic food-grade supports and thus discourage their use by the wine industry.

Clinoptilolite (natural zeolite) is a Ca-hydrated alumino-silicate of volcanic origin, containing a minimum of 85 % clinoptilolite and 15 % maximum of other fiber-free minerals and quartz. It is a highly abundant material of low cost and enhanced mechanical strength with a broad spectrum of uses (industrial, agricultural, environmental, medical, etc) in food processes.

The use of immobilized mixed cultures can be very useful and is usually suggested for the wine industrial sector, as it has been reported to significantly reduce the time needed to complete alcoholic and/or malolactic fermentation.

Kefir is a mixed culture containing yeasts, lactic acid bacteria and occasionally acetic acid bacteria, that co-exist symbiotically and has recently been successfully used in cider and wine fermentations at various temperatures (Nikolaou et al., 2017; Nikolaou et al., 2019).

Hence, the aim of the present study was to evaluate the use of natural zeolites, an inorganic support with multiple technological advantages, for cell immobilization of kefir culture and application of immobilized cells in winemaking.

In the present study, successful immobilization of kefir culture on natural zeolites, types of which are “generally recognized as safe in foods” by the FDA, was investigated, resulting in efficient cell loads in order to perform alcoholic and malolactic fermentation simultaneously.

Immobilization of kefir cells was studied by scanning electron microscopy (Figure 1) and was successful only on the natural zeolites’ surface and cavities.

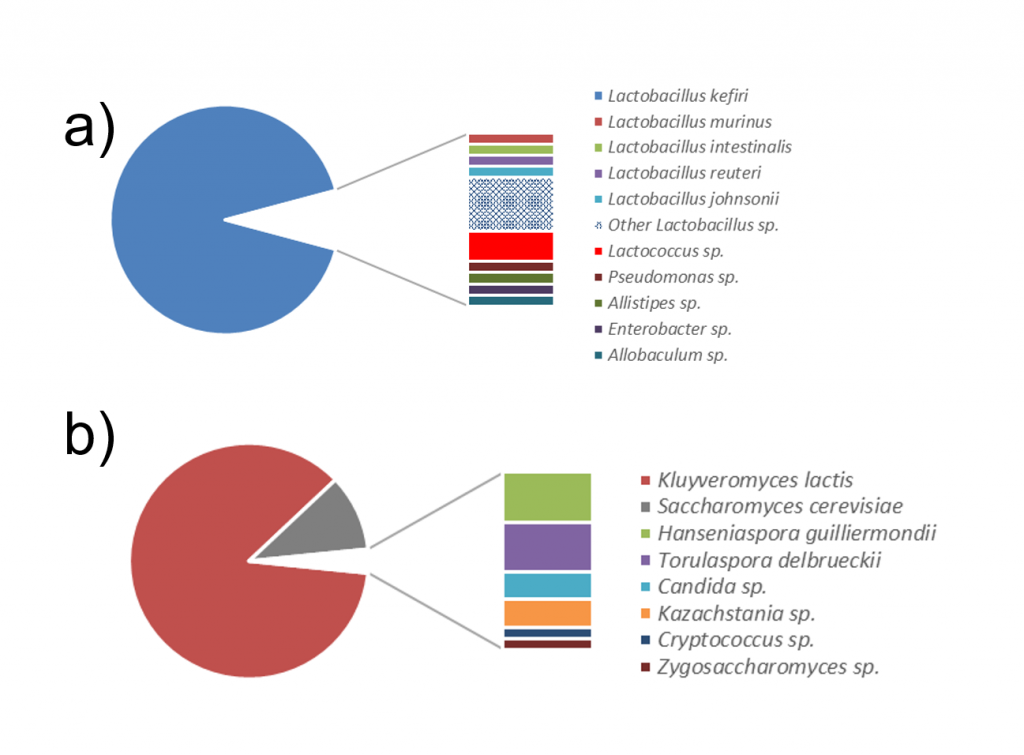

Ιmmobilized kefir cells biodiversity was also studied by Next Generation Sequencing (Figure 2) and was characterized by dominant kefir species both for bacteria [Lactobacillus kefiri (86 %)] and eucaryots [Kluyveromyces lactis (85 %) and Saccharomyces cerevisiae (10 %)]. Sub-dominant species were detected in very low percentages (<1 %).

Fermentation efficiency of the immobilized cells was evaluated with repeated fermentation batches using ~12 οBe grape must (Roditis-Savatiano grape varieties) at various temperatures (5-45 oC), aiming at significant technological and product quality improvements in winemaking.Simultaneous alcoholic and malolactic wine fermentations were monitored for a period >3 months, indicating high operational stability, even at 5 oC.Alcohol content up to 12.5 % vol, malic acid conversion up to 69.2 % and ethanol productivity values several fold higher than those observed in traditional practice were reported in fermentations with immobilized cells on natural zeolites.

Αt 37 oC, the high content of residual sugars and the low alcohol content suggested the suitability of the immobilized kefir culture for the production of novel wine styles, e.g. with reduced alcohol content (Nikolaou et al., 2020) or with a semi-sweet character, while facilitating the flexibility in removal of cells after the end of the fermentation (in appropriate bioreactor systems).

Medium chain fatty acid esters alongside with alcohols considered important for wine bouquet were detected in all samples, contributing fruity, refreshing and floral scents. Principal Component Analysis applied to minor volatiles detected by HS-SPME GC/MS analysis showed that mostly the fermentation temperature affected the wines produced, while the high total ester concentrations detected at 20 οC indicated the high quality of the products.

All new wines were accepted by the tasting panel. Notably, all wines produced with immobilized cells on natural zeolites were dominated by a fruity scent leading to products with improved aromatic profile and quality at various temperatures. Regarding taste, most products were characterized as sour or sweet-sour wines, while at 37 οC, wines produced with immobilized kefir cells on natural zeolites had a sweet taste and a smooth aftertaste, due to the increased residual sugars concentration. Even though no post-fermentation treatments were applied, all new products were of high clarity and were accepted from the tasting panel.

Natural zeolites are proposed as a promising support for kefir culture immobilization. Importantly, the absence of any preparatory stages in contrast to other supports, their high abundancy, their low cost, the ability to be reused and the eco-friendly nature is expected to result in low operational costs and thus allow the scale-up and customization of the proposed technology. The immobilized kefir cells on natural zeolites were found suitable for simultaneous alcoholic and malolactic fermentation at various temperatures ascertaining their high potential in scale-up industrial applications and in the development of novel wine products (low alcohol wines and/or wines with a semi-sweet character). Nevertheless, more research is still required in issues regarding maintenance of cell viability and fermentation efficiency during storage of the immobilized cells between the oenological periods, in order to allow industrial application and meet the modern commercial needs.

Sourced from the research article: Nikolaou, A., Kandylis, P., Kanellaki, M., Kourkoutas, Y. Winemaking using immobilized kefir cells on natural zeolites. LWT, 2020, 133, 110043 https://doi.org/10.1016/j.lwt.2020.110043

Correspondence: anikol@mbg.duth.gr (A. Nikolaou)

Anastasios Nikolaou is a Post-doctoral researcher at the Laboratory of Applied Microbiology & Biotechnology, Department of Molecular Biology & Genetics, Democritus University of Thrace, Alexandroupolis, Greece. He has a Degree in Molecular Biology & Genetics (2011), a Master of Science Degree in Clinical Pharmacology and Therapeutics (2013) and a PhD in Food Biotechnology (2019). He has authored 10 papers in peer-reviewed journals and published 20 conference proceedings. He has been awarded a competitive research scholarship, “Novel wine products using biopreservatives and probiotics”, (funded by the European Social Fund and Greek National Funds) and has participated, as a research associate, in 7 research projects funded from EU, National Grants (Generally Secretary of Research and Technology, Greece) and the Food/Agriculture Industry. His research interests include: functional foods, application of innovative biotechnological technologies for quality improvement of foods, industrial fermentations, exploitation of industrial wastes for production of high added value products, study of microbial ecology in biological samples using molecular techniques.

References

- Kourkoutas, Y., Bekatorou, A., Banat, I. M., Marchant, R., & Koutinas, A. A. (2004). Immobilization technologies and support materials suitable in alcohol beverages production: A review. Food Microbiology, 21(4), 377–397. https://doi.org/10.1016/j. fm.2003.10.005.

- Nikolaou, A., Galanis, A., Kanellaki, M., Tassou, C., Akrida-Demertzi, K., & Kourkoutas, Y. (2017). Assessment of free and immobilized kefir culture in simultaneous alcoholic and malolactic cider fermentations. LWT – Food Science and Technology, 76, 67–78. https://doi.org/10.1016/j.lwt.2016.10.034.

- Nikolaou, A., Sgouros, G., Mitropoulou, G., Santarmaki, V., & Kourkoutas, Y. (2020). Freeze-dried immobilized kefir culture in low alcohol wine-making. Foods, 9(2), 115. https://doi.org/10.3390/foods9020115.

- Nikolaou, A., Tsakiris, A., Kanellaki, M., Bezirtzoglou, E., Akrida-Demertzi, K., & Kourkoutas, Y. (2019). Wine production using free and immobilized kefir culture on natural supports. Food Chemistry, 272, 39–48. https://doi.org/10.1016/j. foodchem.2018.08.015.