Nioi Claudiaa*, Lisanti Maria Tizianab*, Lacampagne Soizica, Pascal Noiletc, Mietton Peuchot Martinea, Ghidossi Rémya

a Université de Bordeaux, Institut des Sciences de la Vigne et du Vin, EA 4577, Unité de recherche Œnologie, 210, chemin de Leysotte, CS 50008, F-33882 Villenave d’Ornon, France. b Università degli Studi di Napoli Federico II, Dipartimento di Agraria-Sezione di Scienze della Vigna e del Vino, Viale Italia, 83100, Avellino, Italy. c Bucher-Vaslin, Rue Gaston Bernier – BP 28, 49290 Chalonnes sur Loire, France

Can membrane technology represent an alternative to thermal process to enhance extraction in red winemaking? In this study we investigated the potentialities of nanofiltration technique (NF) as a non-thermal process to enhance polyphenol extraction during the vinification of Pinot noir grapes. This grape cultivar has a low anthocyanin content compared to other red cultivars [1] so their extraction and also wine color stability are a challenge in the winemaking process.

The new extraction process proposed consists in 3 steps:

- a fraction of the initial volume of must (saignée) was treated by nanofiltration;

- the obtained concentrate (the fraction not passing through the nanofiltration membrane), rich in phenolic compounds, was immediately re-introduced into the fermentation tank;

- the permeate (the fraction passing through the membrane), poor in phenolic compounds, was added on grape pomace at three different fermentation steps, corresponding to a volumic mass of 1.060, 1.030 and 1.000 g.cm-3.

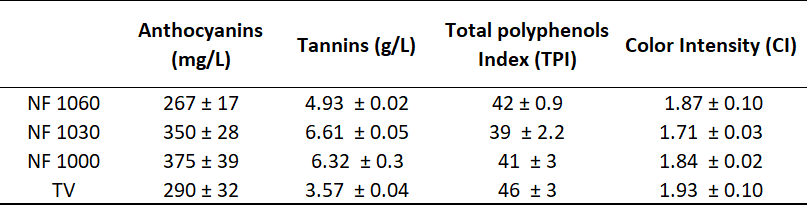

The wines obtained by the NF process were compared with the wine obtained from the same grapes treated by thermovinification (TV). For the TV treatment, the destemmed-crushed grapes were placed in a stainless steel tank and maintained at 80°C for 30 min, by a water-bath system. Then, the grapes were vinified in liquid phase. Polyphenol extraction after TV and NF treatments was evaluated by Total Polyphenol Index (TPI), tannins, anthocyanin and Color Intensity measurements. To evaluate the sensory characteristics of TV and NF wines, sensory analyses were carried on.

Table 1 shows the final concentration of tannins, anthocyanins, total polyphenols index and color intensity of wines after different treatments by NF and TV. The NF treatments with a later addition of the permeate (NF1030 and NF1000) determined an increase in anthocyanin concentration of about 20% for NF1030 and 30% for NF1000, compared to the TV treatment. This could be attributable to the addition of the aqueous phase at the final phase of fermentation that could have enhanced the extraction of the last fractions of anthocyanins still located in the skins. At the same, the tannin concentration was higher in all NF wines, compared to TV wines, especially in NF1030 and NF1000. In both cases, tannin concentration was two times higher. Besides being responsible for astringency in red wine, tannins can combine with anthocyanins in forming co-pigment, thus determining color stabilization. A higher tannin content could be a positive feature for Pinot noir wine, for which color stability is a challenge, especially if ageing is expected [2]. NF 1000 and NF 1060 treatments were able to achieve a total phenol extraction comparable to TV (TPI not significantly different) and the same result was obtained for Color Intensity. Thus, concerning the extraction of color and its stabilization, which is very important for wine from Pinot noir grapes that have poor color development the NF treatment seems to be a suitable alternative to TV.

In addition, the sensory profiles of obtained wines show that the global aroma intensity of the three NF wines was higher than that perceived in TV wine. A general consensus on the greatest appreciation for the wines from nanofiltration treatments, most of all NF1030, was found among judges.

In conclusion, the innovative process proposed in this study proved to be a suitable non-thermal alternative to thermovinification, in terms of extracted anthocyanins, tannins and wine color. The moment of addition of permeate on must had an impact on the quality of the extracted polyphenols. Moreover, the developed process has a great ecological and economical interest. Indeed, the energy consumption associated with thermovinification is 11.6 kWh.hL-1 [3], whereas the average consumption for nanofiltration process in agro-food treatment is lower than about 0.8 kWh.hL-1[4].

See all at:

Nioi Claudia, Lisanti Maria Tiziana, Lacampagne Soizic, Pascal Noilet, Mietton Peuchot Martine and Ghidossi Rémy. Nanofiltration process as non-thermal alternative to thermovinification in Pinot noir winemaking. OENO One, 2020, Vol. 54 No. 1. DOI: https://doi.org/10.20870/oeno-one.2020.54.1.2507

Dr. Claudia NIOI

Associate Professor at the Institute of Vine and Wine Sciences of Bordeaux

University.

Since October 2017: Associate

Professor – Institute of Vine and Wine Sciences of Bordeaux University -Bordeaux

2016 – 2017: Research Engineer – Novasep Process- Lyon

2013 – 2015: Post-doctoral

associate – Chemical Engineering Laboratory-Toulouse

2013: PhD graduation in Food Process Engineering – University of Lorraine

Dr. Claudia NIOI, Food Process Engineer PhD, is currently working at the Institut des Science de la Vigne et du Vin (ISVV) of Bordeaux (France), in development of process applied to enology. She holds her PhD with a thesis on processes to valorize side-product from oil extraction in order to produce molecules with high added value for food safety. Since 2009 her research has been focusing on improve process and on the development of innovative devices for improve extraction and purification of biomolecules with application in different fields. Currently, the impact of process on quality of several matrices (wine and its byproducts) are the main topics of her scientific researches.

REFERENCES

- Mazza G., Fukumoto L., Delaquis P., Girard B.and Ewert B. 1999. Anthocyanins, phenolics, and color of Cabernet franc, Merlot, and Pinot noir wines from British Columbia. Journal Agriculture Food Chemistry, 47(10), 4009-4017.

- Sacchi K., Bisson L.F. and Adams D.O. A., 2005. Review of the Effect of Winemaking Techniques on Phenolic Extraction in Red Wines. American Journal Enology Viticulture 56, 197-206.

- El Darra N., Turk M.F., Ducasse M.A., Grimi N., Maroun R.G., Louka N., and Vorobiev E., 2016. Changes in polyphenol profiles and color composition of freshly fermented model wine due to pulsed electric field, enzymes and thermovinification pretreatments. Food Chemistry. 194, 944-50.

- Gude V.G., 2011.Energy consumption and recovery in reverse osmosis. Desalination and Water Treatment. 36, 239-260.

[…] Science and Wine: Nanofiltration process as non-thermal alternative to thermovinification in Pinot n… […]

[…] Leggi l’articolo completo […]